"Frying bacon" - OK!, "Prying bobbin" - Not so much......

A longarmer called in frustration - every few inches the thread would break, she had checked all the tension settings and thread route, and had even gone as far as to take her bobbin and case to a nearby quilt shop to test them on a similar machine - where they performed flawlessly.

Upon arrival I went through the normal pre-service checklist - serial number, stitch count, several clearance checks such as hopping foot height and made sure the needle was in correctly. Since this longarmer had a Glide Foot I removed it and inspected to ensure it did not have a thread-cut potentially causing the issue, but it was fine - for more info on this issue read this topic: Glide Foot and Thread Shredding.

I slowly rotated the rear handwheel in the quilting rotation direction, and heard a “click-click-click” once per rotation in the hook area and felt significant resistance when rotating the handwheel at that point - even though I had lot of leverage due to the size of the handwheel - time to inspect the hook.

Since something “bad” had clearly happened to the longarm out of an abundance of caution I removed the hook basket which would enable a close inspection without the constraints of the close confines of the hook area of the longarm.

Upon removal I attempted to rotate the inner section against the outer basket, and it would “hang” at a certain point and could not be rotated further. I once encountered a similar issue that turned out to be the broken tip of the needle in the basket - but the longarmer was certain she had not broken a needle - time to look elsewhere.

Upon visual inspection while rotating the inner and outer sections, I noticed the “finger” of the hook basket was bent inwards. Picture 1 (The “finger” is different from the “hook point” - the finger is just a small section of the outer basket - the hook point is a rigid precisely machined “point-and-surface” that starts the magic of stitch formation.

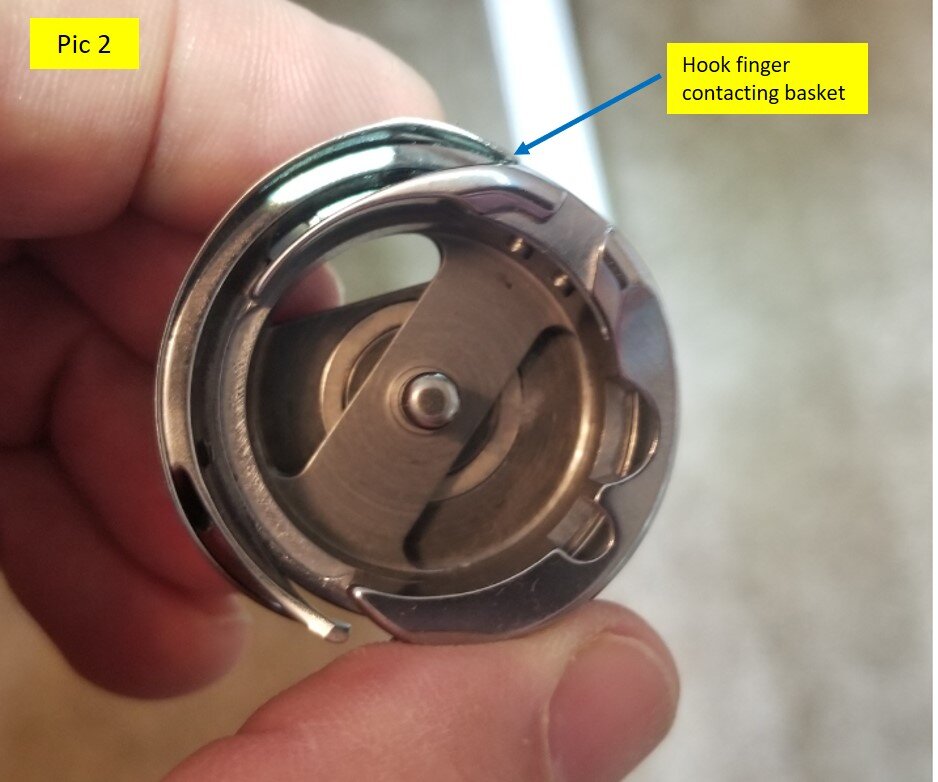

Rotating the inner hook against the outer basket the two would “jam” where the bent hook finger contacted the basket race. Picture 2.

The thread was shredding because there was no space for the thread to exit the bobbin case due to the bent finger.

I used some precision needle-nose pliers and gently bent the finger up until it was in its original position. (Picture 3).

Now that the finger was back in the correct position there was plenty of clearance between the finger and the hook basket as shown in Picture 4.

I installed the hook, timed the longarm, and stitches looked great on both top and bottom after setting tension and there was NO thread-breaks - in fact the longarmer was able to finish a big T-shirt quilt that was on the Frame later than afternoon with no issues.

So…where does the “don’t pry the bobbin” come from?

After discussing the issue with the longarmer she noted that the bobbin had “stuck” and instead of gently pulling the snap-lever or using tweezers to remove the bobbin she had “pried” it out with scissors - thereby bending the finger of the hook.

Fry the heck out of your bacon, but please don’t pry the heck out of your bobbin….

And, as always longarmers….

Quilt On!