Glide Foot Damage Causing Thread Shredding

Thread shredding in certain directions? Are you using a Glide Foot or Glide Foot 2?

You may have a crack/channel/groove in the center.

I recently was summoned to a longarmers studio - despite her best efforts along with my help remotely she could not resolve her longarm shredding and then breaking the thread when it was moved from the front of the quilt area towards the rear at about the 10:30 angle. This longarmer is extremely proficient, runs a business, and quilts more than 200 quilts a year and knows all the normal reasons for thread shredding such as burrs on the thread guide, grit/gunk in the tension assembly disks, bad/damaged needles, and damage to the hook/bobbin/bobbin case, and in this case none of these were the culprit. Just to be safe I checked and verified timing though she had not had an "event" such as stitching scissors or a button and found the timing perfect.

So what gives?

I had her stitch in multiple directions at multiple speeds, and there was no thread-shredding until the machine was moved from front-right towards rear-left at about the 10:30 direction if you had a clock on the longarm with 12:00 at the rear. What could be different in that direction? It could not be the encoders or other common elements as then the shredding would happen in every direction.

Just for grins I had her replace the Glide Foot she was using with a metal foot - and BINGO - no shredding. We then installed a new Glide Foot 2 and again there was no shredding. Why?

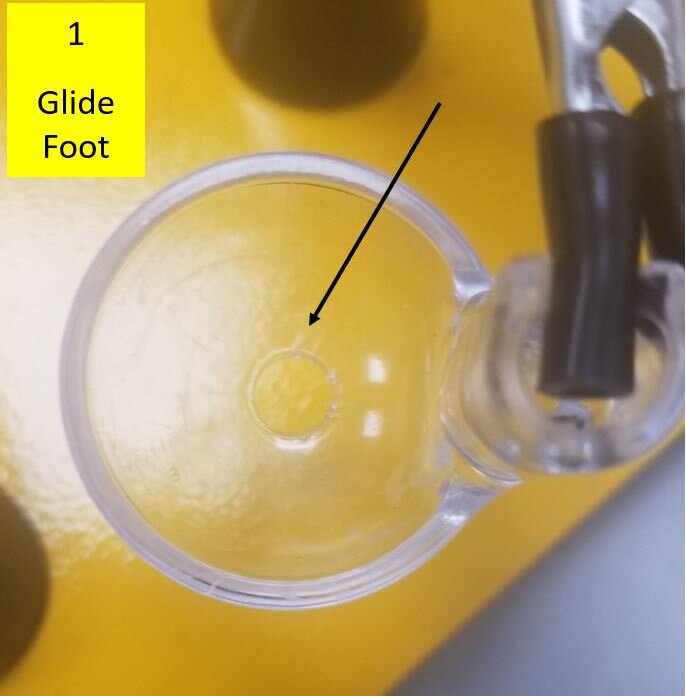

Picture 1 shows the Glide Foot with no magnification - you can see what looks to be a crack noted by the arrow.

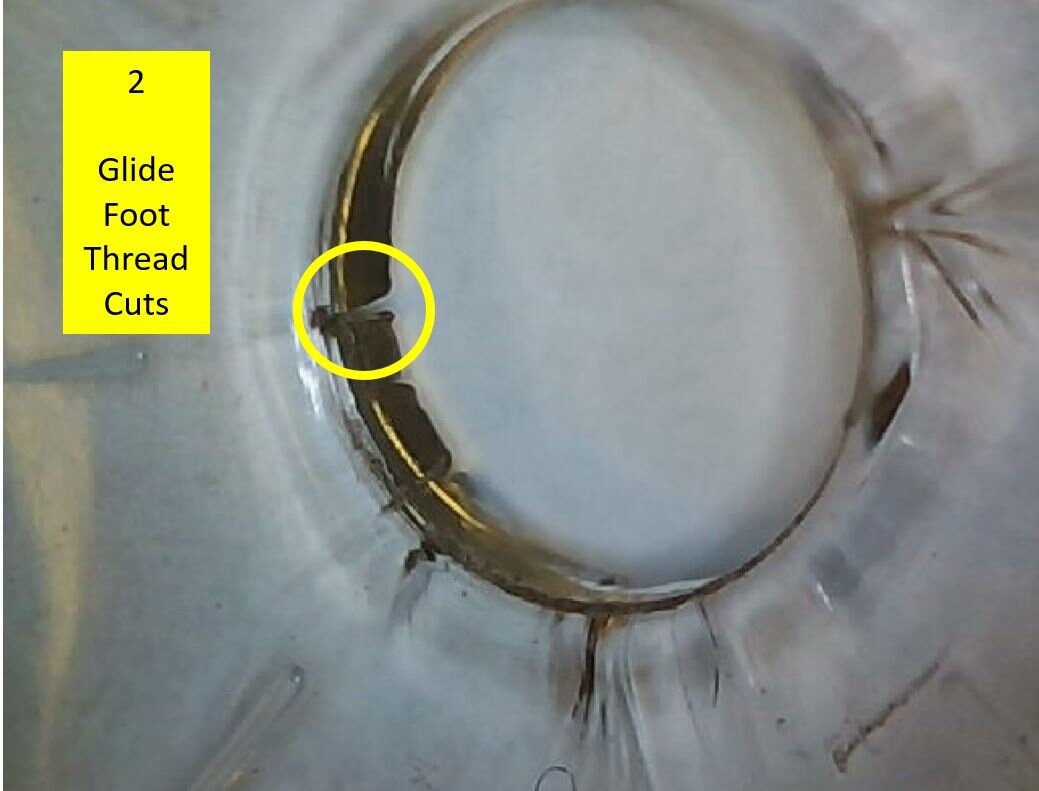

Picture 2 shows the Glide Foot magnified by an endoscope inspection probe - you can clearly see a cut/burn in the edge noted by the yellow circle.

Picture 3 again uses the endoscope and shows a thread in that slot with filaments shredding from the friction of being dragged through it.

As the machine is stitching the thread bounces around and the needle moves (known as needle deflection) and in this case when the machine was pushed towards 10:30 the thread bounced towards that crack and would get hung up in it causing shredding.

So...what caused the crack/slot?

The likely culprit is a too-vigorous pulling up of the bobbin thread after a bobbin change dragging the thread across the plastic edge and essentially sawing/knifing the slot in the Glide Foot. To prevent this damage the bobbin thread should be carefully and gently pulled up through the center of the Glide Foot with care taken to ensure there is no contact with the plastic edge.

Although I have not seen a client use one, there is a foot sold by Quilt Frog that has a metal center and then a plastic bowl to provide the ability to guide the foot over thick seams or other thickness changes without it getting caught that is another option - however - metal can be eventually scored/cut by thread - I have replaced many check springs and a couple of thread guides that over time had been damaged by the thread passing through it at high speed under tension. Ever seen hard granite steps worn away over time by relatively soft shoes? It is the same principle.

If you use a Glide Foot or Glide Foot 2, please be careful to not drag the bobbin thread across the edge of the foot, and if you have shredding in certain directions get a magnifying glass out and see if you have a crack or slot in it.

Do you have questions on this topic or a suggestion for another one you are interested in?