Lost the bobbin light on your longarm? It may have been damaged by aggressive cleaning.

Read MoreCurious if the Hopping Foot Height is within spec on your Handi Quilter, Baby Lock, or Janome Longarm Quilting Machine? Learn how to check and what could cause out-of-spec issues.

Read MoreIf you time longarm machines here is a great tool to make it easier and quicker.

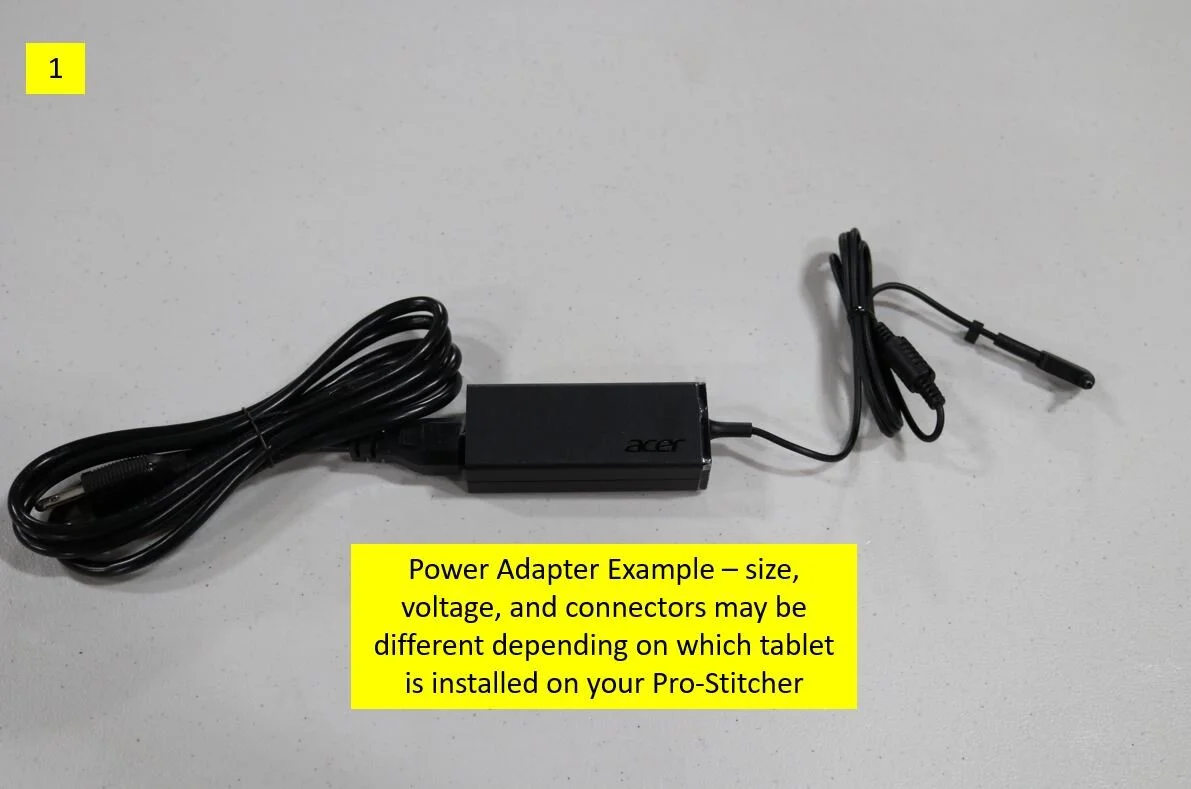

Read MoreIf your longarm is equipped with a Pro-Stitcher or similar computerized quilting platform PLEASE keep the power adapter that came with the tablet - if there is a power failure to the charging port of the tablet you can use the power adapter to continue quilting

Read MoreKeep your scissors away from your needle with a nifty magnet!

Read MoreYour longarm housing is carefully designed to be secured with precise torqueing (tightness) of the fasteners that clamp the sections together. Both too tight and too loose are problems waiting to happen.

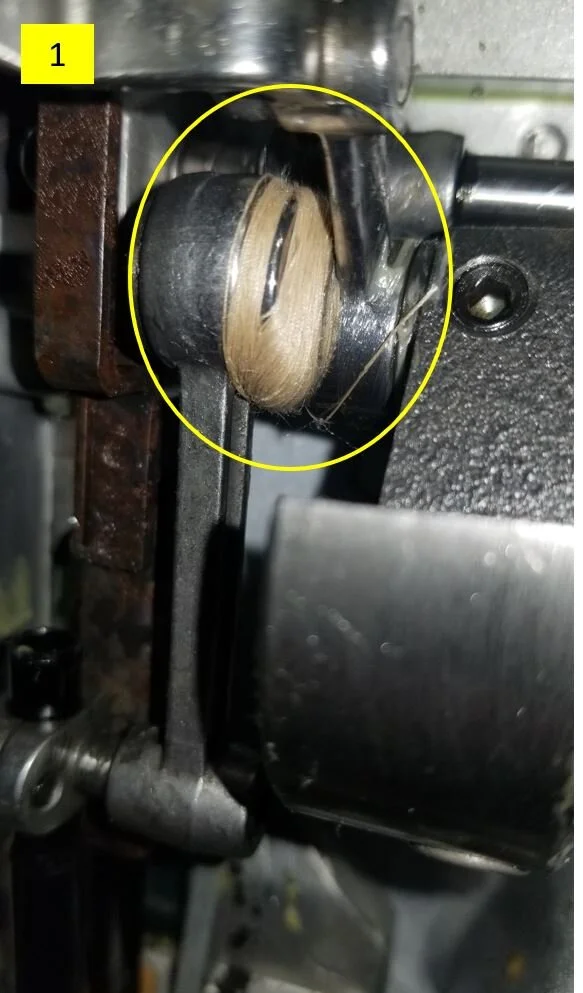

Read MoreIf your longarm breaks a thread and sucks it into the interior it may cause a lockup.

Read MoreIf your longarm doesn’t stitch well or detect motion in certain locations on the Frame, check your cables!

Read MoreIf your backing / quilt sandwich drags as you move your longarm, you may have a damaged needle plate screw.

Read MoreThe check spring is a critical component to ensure proper tension and stitch quality. Over time it can weaken, break, or rust. Longarmers should keep a spare or two - a less than $10 insurance policy.

Read MoreAll longarms need periodic maintenance - and festering problems can be found and corrected before causing longarm performance problems.

Read MoreThe bobbin case spring is an important component to enable quality stitch formation and tension. They weaken over time and need to be replaced - you should keep a spare or two around but make sure you get the right spring for your hook.

Read MoreSkipped stitches and/or shredding thread after a needle “event”? Check your hook.

Read MoreIf your longarm machine does not feel smooth - has bumps/dips/drags/accelerates as you move it around the Frame you may have buildup of “gunk” on the wheels. Learn how to check and resolve.

Read MoreOuch! That made a mark… and a locked-down hopping foot which disabled the longarm. Check all the quilt seams before firing up the longarm.

Read MoreIf your handwheel spins when you crank it but does not spin the pole, you either have a loose bolt or more likely a broken insert. This video will show you how to make an easy repair.

Read MoreThread shredding in certain directions? Are you using a Glide Foot or Glide Foot 2? You may have a crack/channel/groove in the center.

Read MoreIf you notice an Amara, Forte, Regalia, or other similar machine “rocking” as it moves from front-to-rear / rear-to-front on the carriage, and one or more of the wheels of the machine housing are not in constant contact with the carriage, the likely issue is a leveling screw that is out of adjustment.

Read MoreIn every Longarm Forum there are lots of questions and suggestions about changing needle position to enable great stitch quality.

Read MoreIf tension settings have to be set significantly lower or higher than normal - there is a reason for it. Find it and fix it - here’s how.

Read More