Stitch Quality in certain locations left-to-right: encoder tangled in cables!

A local professional longarmer called me about a problem. The problem is “Hazel”, aka a Handi Quilter Forte with a unique personality.

When running the Pro-Stitcher, the needle was not coming all the way up every cycle and would hang/drag in the fabric. I had her check encoder pickup in the Diagnostic screen, and test it in Free Motion. Both worked fine.

Since the machine was working in Free Motion, we assumed the issue was with either the Pro Stitcher program or the computerized carriage.

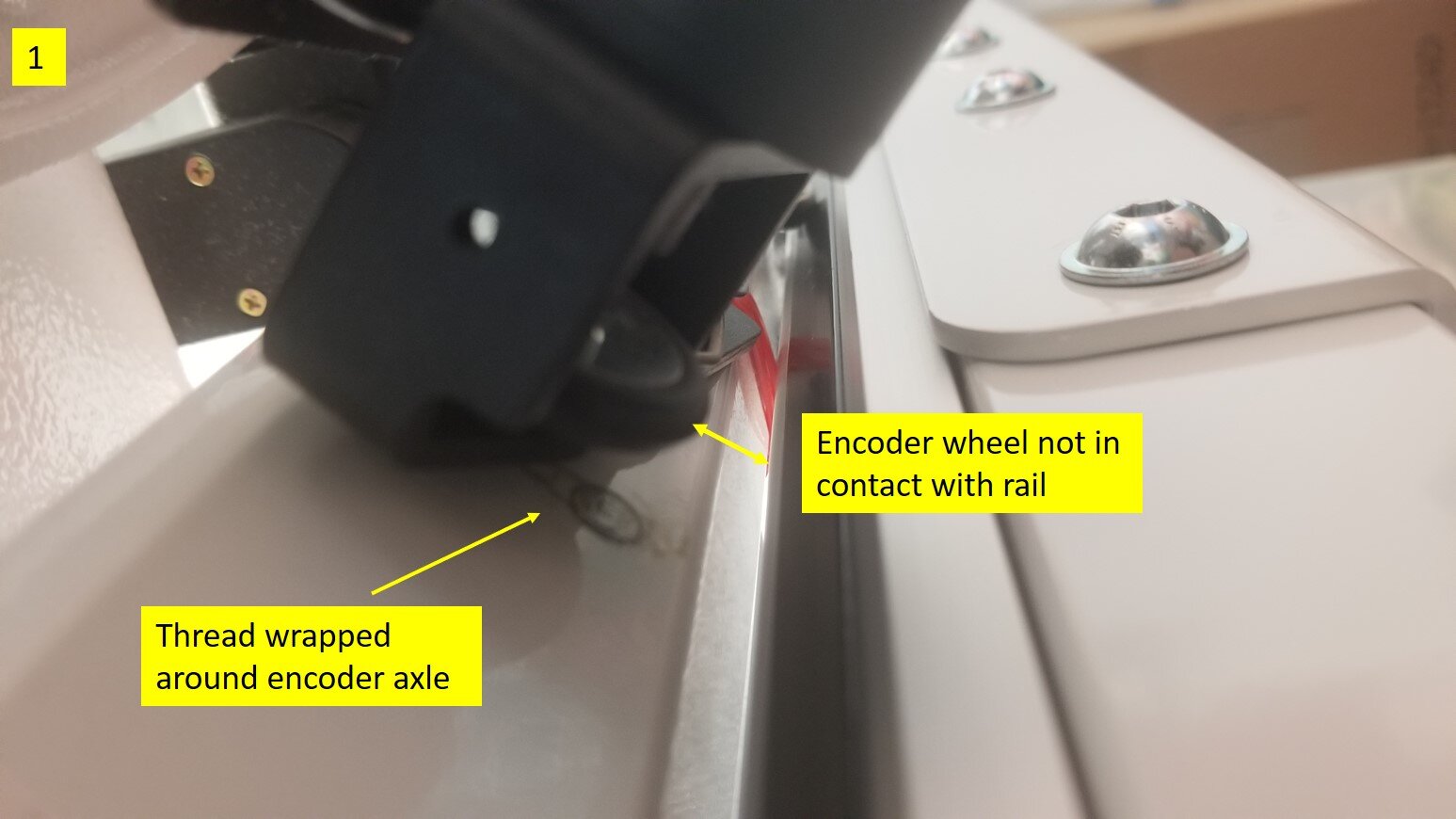

Before I could get out to visit “Hazel”, while doing free motion quilting the customer noticed as the machine moved closer to the front of the Frame the X-axis encoder stopped registering the motion of the machine. She went behind the longarm to inspect and found the Pro-Stitcher cable wrapped around the X-Axis encoder (Pic 2) – and as the machine was moved to the front of the Frame the cable would become taught which would lift the encoder off the rail (Pic 1) so it could not measure motion. She unwrapped the cable and proceeded to knock out a Free-Motion quilt.

When I arrived, we tested the machine in both free-motion and Pro-Stitcher mode – and it worked fine. I had her show me where the cable was (she had a picture – if you have problems with your longarm take pictures or videos of anything important to help the tech). I manually wrapped it, had her move the machine to the front of the Frame, and saw the tire of the encoder lose contact with the rail.

Before we get to the temporary fix, let’s dig into how the longarm and the Pro-Stitcher measure movement and re-position the carriage. The longarm has to measure its movement left-to-right and front-to-rear to enable stitch regulation. As you move the machine faster, the system speeds the needle up to keep the stitch width constant, and vice versa as you slow down its movement. The machine motion is detected by devices called encoders, one that measures left to right movement (The X-Axis) on either the front or rear of the longarm, and a second one the on the machine that measures the machine movement from front-to-rear by detecting the machine moving on the carriage (The Y-Axis).

How about the Pro-Stitcher? The Pro-Stitcher works independently from the longarm encoders – it has belts, gears, and motors that precisely move the machine left-to-right and front-to-rear to move the needle where it needs to be to stitch the pattern, and the encoders pick up the movement of the machine as moved by the ProStitcher (just like if used in Free-Motion quilting) to keep the stitch-width constant.

So….what was causing the needle to drag and not be picked all the way up when the Pro-Stitcher was operating? Once we saw the problem, its pretty simple: as the longarm moved towards the front of the Frame, the control cord wrapped around the encoder would lift the wheel off the rail, and therefore the encoder could not detect X-Axis movement any more, but the ProStitcher didn’t know it so continued to move the machine as per the pattern – and as the X-Axis movement was not detected the machine could not move the needle up as it should – causing the dragging needle. The longarmer was really lucky the needle didn’t hang just a little lower the fabric could have been ripped, the needle broken, and perhaps other mayhem like knocking the machine out of time could have happened.

Now to the fix – the machine was moved several times front-to-rear and vice-versa, and as the communications cable was dangling several inches below the encoder when the machine was at the rear it would be easy for the wrap to happen again. As a temporary fix the communications cable was zip-tied to the power cable (Pic 3) to take some of the slack out of it, and dozens of front-to-rear moves verified there was no stress on the cable but also not enough slack to allow another encoder wrap. Perhaps the manufacturer has a better method to secure the cable – I will be reaching out them and will let the longarm community know if one has been developed and how to implement it.

A couple of key points to keep in mind when troubleshooting inaccurate stitching:

· Check that the encoder tires are making contact EVERYWHERE, all the way from far left-to-right (X-axis) and Front-to-Rear (Y-Axis) – carefully watch or perhaps lightly feel with your finger – and use the diagnostics function if your machine has it.

· If there as a particular spot on the Frame where the problem occurs, look closely at the wires behind the encoder to ensure they aren’t catching on the encoder or something else, and the Y-axis encoder to ensure it is in good contact with the carriage.

The good news is “Hazel” is happy, and you can…

Quilt on!

Do you have questions on this topic or a suggestion for another one you are interested in?